Tuesday was another busy pre-launch day with the team scrambling to troubleshoot some problems that popped up in the middle of the night and get the payload ready to go for the Flight Readiness Review and a possibly Wednesday launch.

I did my best to become one with the hangar and not get in the way. Jimmy kept apologizing for being off working but I was doing my own thing. It was neat to be working on my other NASA projects at NASA.

Plus, it was like live hangar cam!

Some people watch their friends play sports...I watch Jimmy engineer things. It's all about the same.

I've spoken to a few people about the trip since I have returned and it's hard to impress upon folks how novel this whole set up is to someone doing small scale ballooning. CSBF has a huge team of people who take care of many different aspects of the launch from weather to rigging. They make sure that the launch is safe and efficient. They have planes to follow the payload and recover using giant trucks.

I have to hand it to Doug Knight, the brains behind the High Altitude Balloon challenge. He did a fantastic job with the set up of that event. Sure the Flight Readiness Review, check in and late night payload reconstruction bender were all very stressful at the time but I think that it did the best possible job of mimicking a real launch experience on a smaller scale. I saw a lot of parallels here.

One thing that I did learn from this experience with NASA and that I am hoping to impress on all of my students, is the importance of breaks. These folks were working full tilt around the clock, don't get me wrong, but if you're working with your brain, heavy machinery and 12 ft tall ladders you don't want to get too loopy. It can be tempting to push through one "quick thing to finish up." We all do it from time to time. In some cases a short break can keep you safe, recharge your brain and actually lessen the net time it takes to complete a project. Fatigue can lead to careless mistakes and accidents and that is just going to eat up more precious time. I was really impressed when the team left to get milkshakes. I hope my students can learn from this.

I took a break to decompress and eat a peanut butter sandwich at the hotel and saw this gorgeous car!

When I returned to check on Jimmy it had gotten dark and another beautiful moon was visible over the hangar.

He was still working very hard to complete the sunshield. It proved to be a greater design challenge than we initially suspected. Another thing that I learned, or at least was reminded of, during this trip is that at the end of the day most of science and engineering is just winging it. You are trying to do something no one has done before so you have to make it up as you go along. Sometimes it works and sometimes it doesn't. You can't major in balloon engineering. (Yet.)

We had a tarantula visit. It was so unexpected to see one in real life and not in a tank that I wasn't scared of it. I kept my distance but I enjoyed following it around and watching it pace across the hangar. Watch out bunnies!

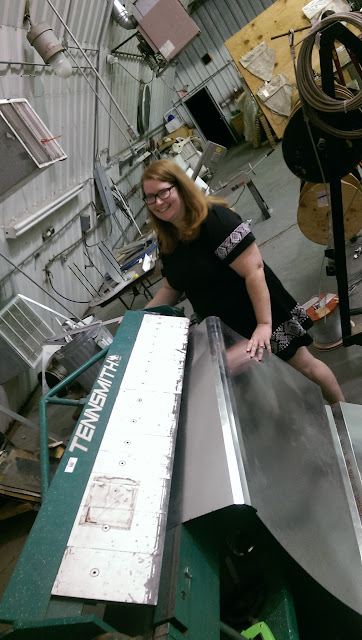

Is it weird to say that I miss the machine shop?

Something about the little details on these machines just makes my skirt fly up.

I told Jimmy I had business in the machine shop and snuck off to take this photo. I have a feeling I'm going to get a lot of mileage out of it.

I'm not sure when we left the base but I know that everyone was still furiously working when we did in anticipation of a 3:30 am roll out. We had the luxury of arriving around 5 am when everything was all set up.

Alas, the fickle weather caused the folks who run the base to wait an hour to see if the wind would settle down in time for an optimal launch. Unfortunately they decided around 6 am to scrub for the day in hopes of better weather later on in the week.

We were disappointed. Sure. But we knew going in that we might not be lucky enough to see the launch in person and honestly, the entire experience was a million times more amazing than I had anticipated even without the grand finale.

The PIPER team was exhausted and certainly not thrilled to hear that they would be spending even more time away from home but they also quickly jumped to the silver lining that they would have more time to perfect all of their systems and fly the payload they hoped to fly and not the most field expedient version. They took the time to secure the payload and then went off to take a much deserved rest but I'm sure that most of them were back at their posts in a few hours.

We were a little sad to leave the base and start the 12 hour journey back to NC but we left with high hopes and big ideas.

The 2.5 hour drive to the airport was not without its own share of excitement...including but not limited to when Jimmy set his cheese balls free.

These are New Mexican cheese balls. They will never be happy in the more humid climes of North Carolina. If you love something set it free, Jimmer. (Actually, no. That hardly ever works out. Maybe you have a 50/50 shot with inanimate food type objects but don't try this with your pets.)

Goodbye noble cheeselike orbs. Thank you for your service. We'll never forget you.

GO! GO! GO!

So in conclusion, because this weird snack food off ramp can't possibly serve as a conclusion....

Thank you to everyone who supported us on this adventure. I can't wait to share what I've learned with my students and the rest of the Unacceptable Risks.